Precast Insulation

Precast Insulation

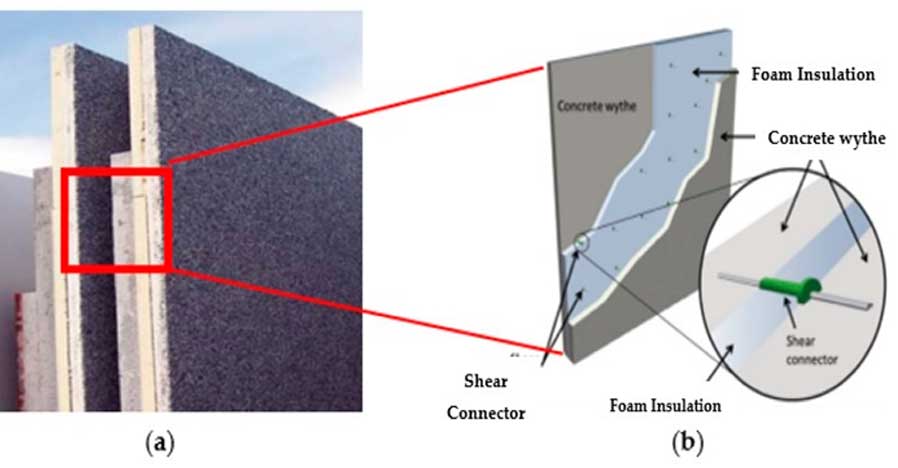

Precast insulation is a specialized insulation solution designed to provide thermal efficiency and protection for precast concrete structures. This type of insulation is typically installed within precast panels or around precast concrete components to enhance energy efficiency, reduce heat transfer, and prevent thermal bridging. Ideal for use in industrial buildings, warehouses, and commercial projects, precast insulation ensures that the structure maintains a stable internal temperature, reducing energy costs and improving overall comfort. It also helps to minimize condensation and moisture-related issues, prolonging the lifespan of the structure.

R-value: The R-value of precast insulation depends on the specific material used, typically ranging from R-5 to R-10 per inch, offering solid thermal performance.

Approximate Cost: The cost of precast insulation varies depending on the material, thickness, and project size, but generally falls between $2.00 to $5.00 per square foot.

Places for Application

- Residential Buildings (walls, floors, roofs)

- Commercial Spaces (offices, warehouses, retail stores)

- Industrial Facilities (factories, distribution centers)

- Cold Storage (refrigerated areas)

- Parking Garages.

- Foundation Systems and Structural Components

Advantages

- Cost-effective upfront investment: Precast insulation panels are produced off-site, which reduces labor costs and allows for faster construction times. This makes them a cost-effective solution for builders and property owners seeking quality insulation without a high initial expense.

- Enhanced soundproofing: Precast panels offer excellent soundproofing properties, reducing noise transfer between rooms or from external sources, creating a quieter and more comfortable indoor environment.

- Lower energy consumption: Precast panels minimize thermal bridging, reducing the need for excessive heating or cooling. This leads to significant savings on energy bills by maintaining more consistent indoor temperatures.

- Easy installation in challenging spaces: The precast manufacturing process allows for customized panels that can be easily installed in complex architectural designs. This flexibility simplifies installation around structural elements without the need for time-consuming adjustments.

Benefits/Results after Application

Precast panels help streamline the construction process, reducing delays and allowing builders to meet deadlines more reliably, which can reduce project management overhead and associated costs.

By blocking sound transmission, precast panels help create more private spaces, making them especially beneficial for buildings like hospitals, hotels, and shared office environments.

By reducing the need for excessive heating and cooling, precast insulation contributes to a building’s overall energy efficiency, supporting green building initiatives and reducing the structure’s carbon footprint.

The off-site manufacturing process ensures that each panel is produced to exacting standards, eliminating the need for on-site modifications and resulting in a higher-quality finish and performance.

Download Brochures

Application Process

Initial Consultation

Work closely with project managers and design teams to evaluate the building's insulation requirements and performance goals.

Custom Insulation Production

Use advanced technology to produce customized insulation materials, tailored to the specific dimensions and thermal needs of the project.

Site Preparation

Prepare the site for insulation installation by ensuring all structural elements are ready for proper attachment and alignment.

Installation and Integration

Professionally install the insulation, making any necessary adjustments to fit around complex structural components, while ensuring proper sealing and attachment for maximum thermal and acoustic efficiency.

Quality Assurance and Final Inspection

Conduct thorough inspections to verify that the insulation is installed correctly, addressing any gaps or weak points, followed by applying protective coatings or finishes as needed.