Rigid Board Installation

Rigid Board Installation

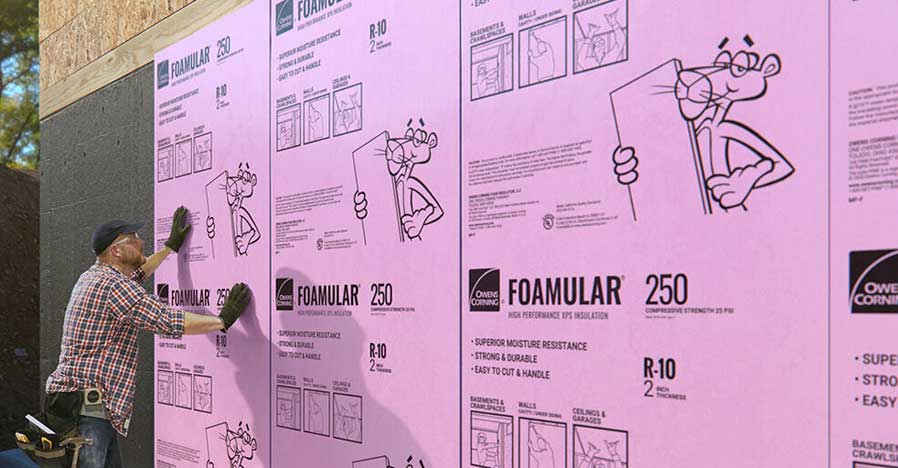

Rigid board insulation involves the installation of high-density insulation panels made from materials such as polystyrene, polyurethane, or polyisocyanurate. These boards offer excellent thermal resistance and are commonly used in a variety of applications, including walls, roofs, and foundations.

In addition to improving energy efficiency, rigid boards provide structural support and moisture resistance, making them an ideal insulation solution for both new and existing buildings.

Places for Application

- Exterior Walls

- Roofs

- Foundations

- Basements

- Attics

- Continuous Exterior Insulation Systems (Residential, Commercial, and Industrial Buildings)

Advantages

- Exceptional Thermal Resistance: Rigid board insulation delivers superior thermal protection, helping to lower energy costs by maintaining consistent indoor temperatures.

- Moisture and Mold Resistance: The dense, durable nature of rigid boards offers added protection against moisture, preventing mold growth and water damage that could compromise the structure.

- Increased Building Durability: The rigidity and durability of these boards not only provide insulation but also contribute to the structural integrity of walls and roofs, enhancing the overall stability of the building.

- Versatile Application: Rigid boards are ideal for a range of applications, including both above-ground and below-ground installations, and can be retrofitted to older structures as well as new builds.

Benefits/Results after Application

Rigid boards effectively reduce heat transfer, resulting in lower heating and cooling costs while improving indoor comfort levels year-round.

With their moisture-resistant properties, rigid boards help prevent water infiltration and mold growth, ensuring long-term protection for your building.

The rigidity of the insulation boards adds extra strength to walls, roofs, and foundations, improving the overall stability and lifespan of the building.

Whether for retrofitting or new construction, rigid board insulation is a long-lasting solution that requires minimal maintenance and degradation over time.

Download Brochures

Application Process

Site Assessment and Measurement

We begin by evaluating the area to be insulated and taking precise measurements to ensure a perfect fit for the rigid boards.

Cutting and Fitting

Rigid boards are cut to the required size and shape to fit the walls, roof, or foundation. The boards are then fastened securely to the structure.

Sealing the Seams

To prevent air leakage and maximize insulation performance, all seams and edges are carefully sealed using appropriate materials such as tape or spray foam.

Final Inspection and Adjustment

After installation, the entire area is inspected to ensure proper insulation coverage and structural integrity.

Rigid board insulation is a reliable, long-term solution for improving energy efficiency, moisture resistance, and structural stability in a wide range of building applications.